What is poly poly core spun polyester sewing thread?

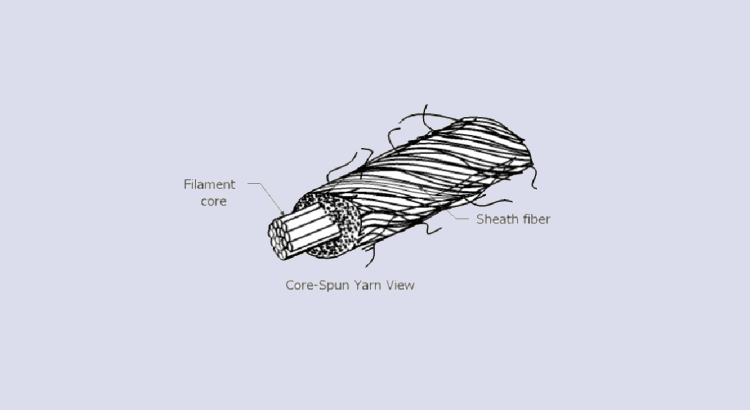

The poly poly core sewing thread (core spun polyester sewing thread) is made of polyester filament yarn as the core, and the outer part is covered with spun polyester. The finished product is dyed at a high temperature of 130 ° C.

Features: The poly poly core spun polyester sewing thread has the appearance of spun polyester sewing thread, but the strength is higher and more balanced. The product has moderate toughness, tight stitching, excellent low shrinkage, good wear resistance, excellent antistatic properties and Corrosion resistance.

Therefore, the poly poly core spun polyester sewing thread is suitable for high-speed sewing, and it is necessary to sew a relatively firm garment.

Performance advantages:

1. The strength of the same specification is 40%-50% higher than that of ordinary spun polyester sewing thread.

2. Excellent seam ability for both hand sewing and automatic machine operation.

3. Conducive to reducing joint cracking and ineffective sewing.

4. Significantly reduce the jumper and disconnection after completion.

Standing model: 45/2, 40/2, 38/2, 28/2, 20/2, etc.

Application: suits, shirts, denim, thin knit, suits, formal wear, etc.

Detailed Description: The poly poly core spun polyester sewing thread is a high quality core spun polyester sewing thread. It is made of polyester filament yarn and the outer layer is made of spun polyester, which is suitable for most sewing applications. Poly poly core spun polyester sewing thread has higher strength and sewing properties than spun polyester, allowing the use of thinner wires.

Poly poly core spun polyester sewing thread minimizes sewing problems while maximizing sewing quality. In recent years, with the continuous improvement of labor production efficiency and the large-scale popularization and use of high-speed sewing machines, the application range of the poly poly core spun polyester sewing thread has been continuously expanded.

Because of the friction between the needle and the fabric during high-speed sewing, a large amount of heat is generated; when the number of layers to be sewn is increased (such as a shirt collar), the temperature of the needle is sharply increased, especially at a sewing speed of 5,000 stitches. Above /min, the needle will exceed 300 ° C, while the high-strength polyester filament has a melting point of 255 ° C – 260 ° C, resulting in a fragile polyester filament. The use of the poly poly core spun polyester sewing thread can avoid the above problem, because the polyester filament core sewing thread in the core thread is made by using high-strength polyester filament to wrap the spun polyester staple fiber. This product has the high strength of polyester filament sewing thread and the natural hairiness and feel of spun polyester sewing thread. It is very suitable for high-speed sewing. It can fully meet the requirements of fabric style and other technical fields. has Broad development prospect.