UHMWPE Thread

Color: Raw white

Specifications: 50d/2, 100d/2, 200d/2/3, etc

Tube type: Loose tube (170mm, 230mm)

Usage: Sewing, Quilting

Material: 100% polyester filament

Packaging: cardboard box, other

Customization: Specifications and packaging can be customized

Definition

Ultra high molecular weight polyethylene (UHMWPE) fiber yarn with it’s density of 0,97g/cm³, a modulus of 1150 cN/dtex and a tensile strength of 32 cN/dtex is a perfect yarn for high end applications.

The UHMWPE fiber (Ultra High Molecular Weight Polyethylene Yarn) has 15 times stronger than steel and 40% stronger than aramid when weight for weight basis. It is the strongest yarn today for making cut-resistance gloves, high-strength ropes, and bulletproof fabrics. Its tenacity at breaking up to 45g/D and has goods performance on anti-UV, anti-chemicals, and anti-cut.

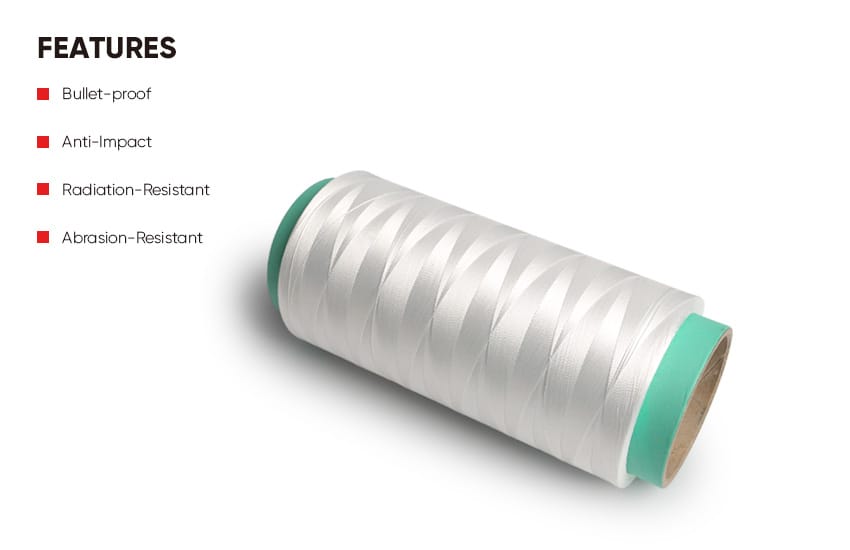

Product Features

- BULLET-PROOF

- Anti-Impact

- Light Weight

- Anti-UV

- Corrosion-Resistant

- Dimensional Stability

- Radiation-Resistant

Abrasion-Resistant

Typical Technical Properties

- After 1500 Sunshine hours, its remaining strength is more than 80%.

- After 6 months in most chemicals (seawater, gas, etc.), its remaining strength is 100%.

- The UHMWPE ropes remaining strength is 100% after 1000 times loaded relative test.

- Melting Point is around 135-145, Highly resistant to abrasion, cutting, tearing

- Its relative times until break of Abrasion proof are more than 110 to 103.

- Its relative times until break of Winding proof are more than 110 to 103.

- Its strength of annulation is 12 up to 18g/d. its 10 up to 15g/d for collusion.

Color is bright white and poor for dyeing.

Table

Construction:UHMWPE Thread

Ne:50d/2

Tenacity(cN/dtex): 28

Liner Density(C.V.%): ±3

Breaking Strength(N): >30

Elongation At Break: 3.50%

Ne:100d/2

Tenacity(cN/dtex): 28

Liner Density(C.V.%): ±3

Breaking Strength(N): >60

Elongation At Break: 3.50%

Ne:200d/2

Tenacity(cN/dtex): 28

Liner Density(C.V.%): ±3

Breaking Strength(N): >122

Elongation At Break: 3.50%

Ne:200d/3

Tenacity(cN/dtex): 28

Liner Density(C.V.%): ±3

Breaking Strength(N): >182

Elongation At Break: 3.50%

Ne:4000d/2

Tenacity(cN/dtex): 28

Liner Density(C.V.%): ±3

Breaking Strength(N): >240

Elongation At Break: 3.50%

Ne:400d/3

Tenacity(cN/dtex): 28

Liner Density(C.V.%): ±3

Breaking Strength(N): >362

Elongation At Break: 3.50%

| SPECIFICATION | TENACITY (cN/dtex) | LINER DENSITY (C.V.%) | BREAKING STRENGTH (N) | ELONGATION AT BREAK |

| 50D/2 | 28 | ±3 | >30 | 3.50% |

| 100D/2 | 28 | ±3 | >60 | 3.50% |

| 200D/2 | 28 | ±3 | >122 | 3.50% |

| 200D/3 | 28 | ±3 | >182 | 3.50% |

| 400D/2 | 28 | ±3 | >240 | 3.50% |

| 400D/3 | 28 | ±3 | >362 | 3.50% |

| SPECIFICATION | TENACITY (cN/dtex) | LINER DENSITY (C.V.%) | BREAKING STRENGTH (N) | ELONGATION AT BREAK |

| 50D/2 | 28 | ±3 | >30 | 3.50% |

| 100D/2 | 28 | ±3 | >60 | 3.50% |

| 200D/2 | 28 | ±3 | >122 | 3.50% |

| 200D/3 | 28 | ±3 | >182 | 3.50% |

| 400D/2 | 28 | ±3 | >240 | 3.50% |

| 400D/3 | 28 | ±3 | >362 | 3.50% |